R-5.6

Note: Installation instructions and illustrated drawings are recommendations only, while proper local construction methods are the responsibility of the installer.

Note: Installation instructions and illustrated drawings are recommendations only, while proper local construction methods are the responsibility of the installer.

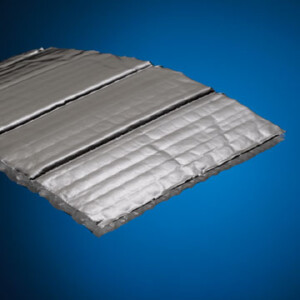

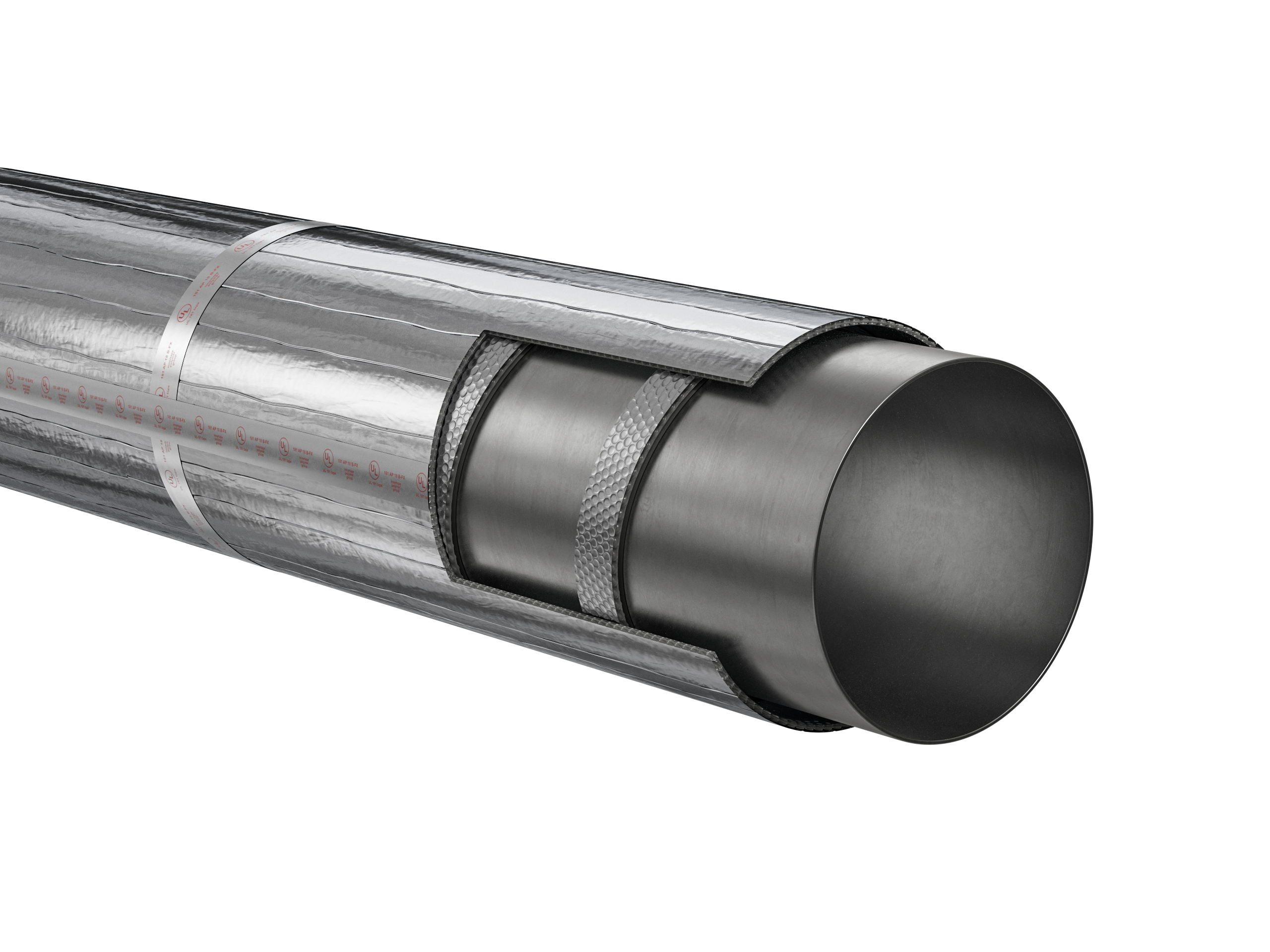

Reflectix® Duct Insulation is an alternative to other types of fibrous insulation products. Ease of handling and quick installation make Reflectix® the first choice when selecting insulation for outdoor round or rectangular ductwork. The product provides an R-5.6 when installed with a 0.375” air gap between the duct and the insulation.

Product Description

Reflectix® Outdoor Duct Insulation consists of two outer layers of aluminum foil that reflect 97% of radiant heat. The outside layer of foil is made of heavier foil. Each layer of foil is bonded to a tough layer of polyethylene for strength. Two inner layers of insulating bubbles resist conductive heat flow while a center layer of polyethylene gives Reflectix® high reliability and strength.

Benefits

- Wrap rectangular or round ductwork in HVAC applications

- Heating costs can be greatly reduced

- Eliminate unnecessary heat loss / gain and air leakage

- Helps to ensure consistent temperatures

- Non-toxic / non-carcinogenic

- Fiber-free

- Lowers heating and cooling costs year-round

- Reflects 97% radiant heat

- Costs less to install

- Lightweight and clean

- Not affected by moisture or humidity

- Does not promote nesting of birds, insects or rodents

- Resists growth of fungi, mold and mildew

- Does not require protective clothing or respirators to install

- ISO 9001:2015 certified manufacturing location

Part Numbers and Sizes

- CDW48050 (48”x 50’)

Technical Data

- Temperature Range: 250 Operational

- Nominal Thickness: 5/16 inch (.312)

- Weight: 1.25 oz./sq. ft.

- Flame Spread Index (ASTM E 84): Less than 25

- Smoke Developed Index (ASTM E 84): Less than 50

- Fire Rating: Class A/Class 1

- Linear Shrinkage: None

- Reflectance (IR): 97%

- Water Vapor Transmission (ASTM E 96): 0.02

- Puncture Resistance: 60 lb./in.

- Mold and Mildew: No Growth

- Emittance: 0.03

- Tensile Strength: 3.7 N/mm

- Pliability: No Cracking

- Hot Surface Performance: Passed

Note: Not for use in direct contact on surface temperatures that are 180 F or greater.

Testing and Certification

- Thermal Performance ASTM C518

- Hot Surface Performance ASTM C411

- Flame Spread and Smoke Density ASTM E84

- Fungus Resistance Mil-Std 810B Method 508

- Pliability Test ASTM C1224

- Water Vapor Transmission ASTM E96

- Tensile Strength ASTM C751

- Emittance Testing ASTM C1371

- State of California

- State of California Licensed Insulation Manufacturer

- State of Minnesota: Filed with Minnesota Insulation Standards Program

- R&D Services Emittance Testing

- Warnock Hersey Professional Services, LTD: Physical Properties Sheet Width, Length, Pliability, Water Vapor Permanence and Aged Water Vapor Permanence Report # 1/92

- Warnock Hersey Professional Services, LTD: Water Vapor Transmission Test ASTM-E96 (Dessicant Method) Report # 1/91

Installation Instructions

Note: Installation instructions and illustrated drawings are recommendations only, while proper local construction methods are the responsibility of the installer.

Spacer Wrapped in a Candy Cane Fashion

Spacer: HVSPW02025 (Reflectix® Spiral Pipe Wrap 2”x 25’)

- Refer to the two diagrams above.

- Make sure all sheet metal joints, seams and penetrations are sealed.

- Wrap and secure spacer material to the duct in a candy cane fashion. Proceed down the duct in one direction with a repeat of the wrap at 12” intervals. Use Butyl Foil Tape to fasten the spacer in place.

- Verify the circumference of the duct with the spacer strip in place.

- Cut the Reflectix® product to this length plus 1”.

- Wrap the product around the duct and securely tape the linear and circumference seams (overlapping 1”- 2”) with Butyl Foil Tape (goal is an air-tight, snug seam seal).

- Note: The heavier “reflective layer” side of the product should face the environmental elements.

- Do not leave any exposed duct or space where air can enter between the duct and the Reflectix®.

Please Note Regarding Hangers:

Strap Hanger: Wrap Reflectix® with the seam at the hanger. Tape seam tightly around hanger.

Saddle Hanger: Make sure that there is a spacer below the hanger, between the insulation and the duct, to prevent the insulation from touching the duct.

Important

Review These Important Safety Guidelines Prior to Installation:

- ALWAYS check local building codes before installing Reflectix®.

- ALWAYS check the area you are insulating and make any needed repairs. Any worn wiring should be replaced before you begin installing Reflectix®.

- ALWAYS make sure work areas are well ventilated and well lighted.

- ALWAYS use eye protection when operating a staple gun.

- ALWAYS use caution and common sense when using a staple gun. Be aware of electrical wiring locations. Stapling into a wire can cause severe shock or death. NEVER staple into electrical wiring.

- ALWAYS be careful when working with large pieces of Reflectix® on windy days.

- When installing Reflectix® on bright sunny days, it is best to wear sun glasses.

- Do not work in areas such as attics when temperatures are too hot.

- Please Note: The intention of these Installation Instructions and 3-D renderings are for the sole purpose of illustrating the correct location and relative position of the Reflectix® products in specific building assemblies. The correct construction methods and techniques are the responsibility of the installer or contractor. The methods outlined are recommendations on location of the Reflectix® products as a guideline. There are no claims on the part of Reflectix, Inc. that these building assemblies are finite standards or meet building code requirements (as they can vary by region).

Photos

Pictured: 1. Outdoor Duct Insulation, 2 and 3. Outdoor Duct Insulation Close-up